Impatient, huh!WildBill wrote:

Alright, first of all, creep in typical metals is caused by a combination of high temperature and stress over time. Permanent deformation will occur at stresses well below the ultimate yield strength. Although plastics and lead will exhibit creep at room temperature, noticeable creep in metals typically starts at about 1/3 of melting temperature. For ordinary carbon steel, for example, 800 degrees F is a typical initial creep temperature. A typical engineering application would be in steam boilers, turbines, or jet engines -- not magazine springs.

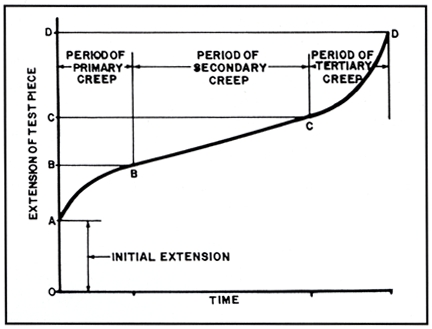

Creep exhibits 4 phases in the process. First, there is a measurable change in length immediately, shown below as the initial extension from point O to point A. Second, there is a rapid change in length where the rate of change flattens out called primary creep. The secondary creep is roughly linear and can last for years. The tertiary creep at the end is more rapid, leading to failure.

Since creep is predominantly a high temperature issue not relevant to magazine springs, the more relevant question is whether your magazine spring was designed below it's fatigue limit -- which means it should last beyond your lifetime -- or if it was designed for stress at some point above the fatigue limit but below its YTS limit , which means there is a true "lifespan" for a magazine spring before it fails from fatigue after a number of load/unload cycles. (Note again, if does not fail from simply sitting compressed for any number of years.)

Well, without reviewing the actual drawings, no engineer could say for sure how many cycles a magazine spring was designed to endure before failure. Again, I'll say expect a quality mag spring to soak up AT LEAST a thousand cycles. If you have enough ammo to be worrying about that many cycles, buy a spare mag or two. If you are worried about it, it is cheap to replace the mag springs anyway.

Also, simple experimentation proves that the mag spring operates below its YTS:

-Take the spring out and lay it relaxed on a flat surface. Measure the overall length from one end to the other.

-Put the spring back in the magbody.

-Load the mag to the recommended capacity.

-Unload the mag (you don't have to shoot them off, but it is more fun that way).

-Remove the spring from the magbody and re-measure. If no different than before then we're obviously not deforming the spring. Therefor the design is under the YTS.

Heck, you could probably fully compress most mag springs without hurting them. Now if you STRETCH them, that's another matter. I have yielded mag springs that way - and promptly replaced them.